Genlis Métal a développé deux activités principales

La valorisation des carottes et sous-produits de Fonderie sous-pression zinc

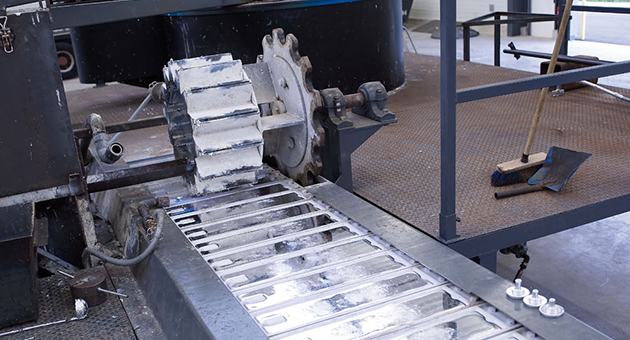

Cette activité consiste à fusionner les «carottes» de fonderie, éliminer les écumes et les remettre au titre pour produire des alliages de zinc normalisés qui sont ré-utilisés par les fondeurs. Alliage à empreinte carbone réduite de plus de 95% par rapport aux alliages élaborés à partir de Z1 (SHG)

Cette activité consiste à fusionner les «carottes» de fonderie, éliminer les écumes et les remettre au titre pour produire des alliages de zinc normalisés qui sont ré-utilisés par les fondeurs. Alliage à empreinte carbone réduite de plus de 95% par rapport aux alliages élaborés à partir de Z1 (SHG)

La production d’alliages de zinc (base Z1) normalisés pour la Galvanisation de l’acier (galvanisation générale, continue et du fil)

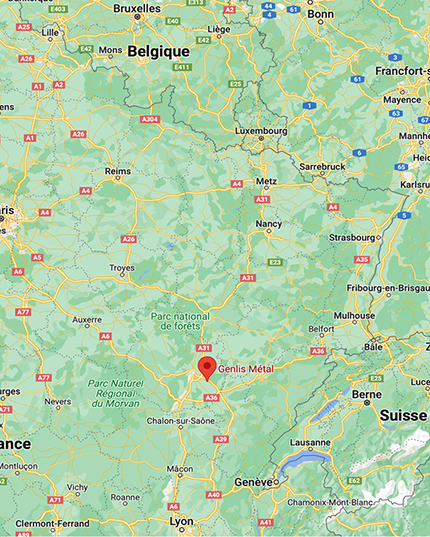

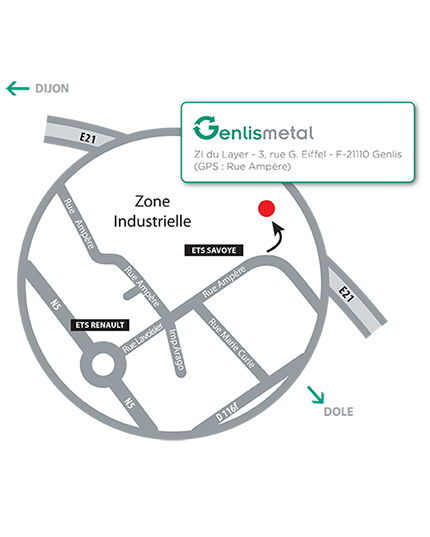

Genlis Métal est idéalement située au cœur du marché français de la fonderie zinc et à proximité des principales unités de galvanisation.

Ainsi, notre situation géographique vous permettra de minimiser les coûts de transport des matières (jets de coulées ou alliages de zinc).

Genlis Métal est également en mesure de vous servir rapidement dans les pays limitrophes et en Europe en général..

Ainsi, notre situation géographique vous permettra de minimiser les coûts de transport des matières (jets de coulées ou alliages de zinc).

Genlis Métal est également en mesure de vous servir rapidement dans les pays limitrophes et en Europe en général..

Nos produits

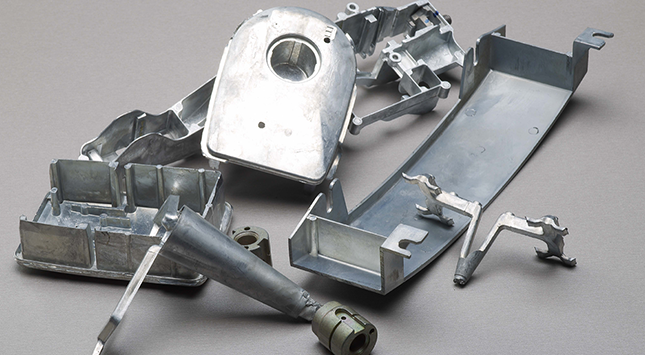

Valorisation des jets de coulée de fonderie zinc.

Genlis Métal collecte les jets de coulée des fondeurs zinc et les pièces moulées défectueuses, les refond et les remets à titre pour produire des alliages de zinc normalisés qui retournent chez les fondeurs qui les utilisent dans leurs applications originelles.

Ces produits valorisés sont des alliages Zamak qui répondent aux normes européennes en vigueur (voir Fiches techniques).

Production d’alliages primaires sur base Z1 (SHG 99,995%).

ZAMAK : Genlis Métal peut également produire les alliages Zamak au départ de zinc Z1 ou SHG 99,995% (contenant moins de 50 grammes d’impuretés par tonne).

Les alliages Zamak 2, 3 & 5 normalisés à base de zinc, aluminium et cuivre sont régulièrement produits.

ZAMAK : Genlis Métal peut également produire les alliages Zamak au départ de zinc Z1 ou SHG 99,995% (contenant moins de 50 grammes d’impuretés par tonne).

Les alliages Zamak 2, 3 & 5 normalisés à base de zinc, aluminium et cuivre sont régulièrement produits.

Contact ZI du Layer • 3, rue G. Eiffel • 21110 Genlis • FRANCE • tél. +33 (0)3 80 45 91 40 • fax +33 (0)3 80 45 91 49